Table of Content

- Liquid Penetrant Examination

- Procedure for Liquid Penetrant Examination (LPE)

- Applications of Liquid Penetrant Examination

- Key Takeaways

- FAQS

Liquid Penetrant Testing is a surface defect detection method, that can be used on any material (i.e. non-ferrous, conductive or non-conductive, metals/non-metals). At its core, LPI involves the application of penetrants, which come in two primary forms, to surfaces requiring inspection. These penetrants, whether used in welding joint DP tests or general liquid penetration testing, seep into surface discontinuities, including cracks and lack of fusion, enabling accurate defect detection.

Liquid Penetrant Examination(PT): An Overview

Liquid Penetrant Examination (LPE), commonly known as Dye Penetrant Inspection or liquid penetrant testing, is a widely used non-destructive testing method to detect surface defects and discontinuities in various materials. Liquid Penetrant Examination can be carried out on castings, raw materials, machined faces, and Weld Joints. It is more often used in Austenitic Stainless Steels, where MPI inspection is not practically possible. However, PT is limited to materials having a porous surface or very rough surface.

Most standards insist that the penetrant materials used, should not contain contaminants that spoil the quality of weld and metals. ( contaminants such as Sulphur, Chlorine & halogens ) Penetrant materials are mostly suitable for materials with surface temperatures less than 52°C. Therefore the weld has to be allowed to cool before carrying out a PT test on it.

Dive In: A Complete Guide on Liquid Penetrant Testing

What is the Liquid Penetrant Examination Procedure?

Liquid Penetrant Inspection is not merely about detecting flaws; it embodies a commitment to quality, safety, and reliability. Through seamless integration into manufacturing, maintenance, and quality control processes, LPI plays a pivotal role in upholding industry standards and ensuring the integrity of critical components. This step-by-step procedure outlines the key stages involved in conducting an LPE.

1. Pre-cleaning

Before commencing the examination, it is essential to pre-clean the test surface thoroughly. This step involves removing any dirt, grease, oil, paint, or other contaminants that might obstruct the penetration of the liquid dye. A clean surface ensures that the penetrant can access surface defects effectively, preventing false indications during the examination.

2. Application of Penetrant

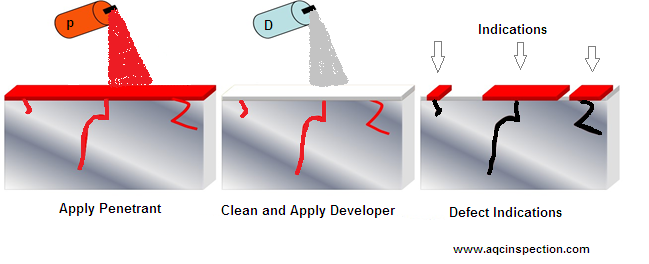

Once the surface is clean and dry, the liquid penetrant is evenly applied to the test area. The penetrant is left to dwell for a specified period, usually determined by the material and the type of penetrant being used. During the dwell time, the penetrant seeps into any surface defects present on the material.

3. Penetrant Dwell Time

The Dwell Time is a critical stage in the LPE process. The time the penetrant is allowed to remain on the surface directly affects the sensitivity of defect detection. Longer dwell times generally lead to increased penetrant absorption into defects, resulting in higher sensitivity. However, excessively long dwell times might cause the penetrant to dry out on the surface, reducing its ability to penetrate smaller defects. Striking the right balance in dwell time is essential for obtaining accurate and reliable results.

4. Penetrant Removal

After the dwell time has elapsed, the excess penetrant is carefully removed from the surface. The removal process should be carried out meticulously to avoid unintentionally wiping away penetrants from actual defects, which could lead to false-negative results. Some methods of penetrant removal include solvent wiping, water rinsing, or using special emulsifiers.

5. Application of the Developer

Following the removal of the excess penetrant, a developer is applied to the surface. The developer acts as an absorbent, drawing the trapped penetrant out of the defects and making them visible. There are various types of developers, including dry powders and wet suspensions, each offering different benefits depending on the specific inspection requirements.

6. Inspection

The developer brings out the indications of defects on the surface, which can now be inspected under appropriate lighting conditions. Adequate lighting, often achieved through ultraviolet lamps, enhances the visibility of indications. Trained NDT Inspectors carefully examine and interpret the indications, considering their size, shape, and location, to assess the significance of the detected defects.

7. Post-cleaning

After completing the inspection and recording the results, the test surface is thoroughly post-cleaned. This step is essential to remove any residual penetrant and developer from the surface, ensuring that subsequent inspections or other processes are not affected.

The Applications of LPE

Liquid Penetrant Examination (LPE) is a versatile NDT method that finds extensive applications across various industries. It involves the application of a penetrating liquid, typically a coloured dye or fluorescent dye, to the surface of a material. Let's explore some of the diverse applications of LPE in different sectors:

1. Manufacturing Industry

In the manufacturing of turbine blades for gas turbines, LPE is employed to detect surface cracks, porosity, and other defects that could compromise the integrity and performance of the blades. Early detection of such defects ensures that only flawless components are used in critical applications.

2. Aerospace Industry

During regular maintenance inspections of aircraft engines, LPE is used to detect cracks or defects on the surface of turbine blades and compressor discs. Identifying flaws early on helps prevent potential engine failures and enhances flight safety.

3. Automotive Industry

In the production of automotive engine blocks, LPE is applied to identify surface cracks and defects. By using LPE as part of the quality control process, manufacturers can ensure that the engine blocks meet the required standards and do not contain any defects that could compromise performance.

4. Weld Inspections

In the construction of Pressure Vessels, LPE is employed to inspect welds for any defects that might weaken the structure. The ability of LPE to identify surface flaws aids in maintaining the structural integrity and safety of pressure vessels used in various industrial processes.

5. Power Generation Industry

In nuclear power plants, LPE is used to examine critical components for surface cracks and discontinuities. Early detection of defects in these components ensures the safe and efficient operation of nuclear power plants.

Key Takeaways

- Liquid Penetrant Examination (LPE) is widely applicable in industries like manufacturing, aerospace, automotive, weld inspections, power generation, and petrochemicals, ensuring safety and reliability across diverse components and structures.

- LPE offers enhanced sensitivity, particularly with fluorescent penetrants, ensuring accurate detection of even minute surface defects, thus preventing potential failures and accidents.

- Adherence to industry standards like ASME Section V is crucial. Qualified personnel, trained according to ASNT norms and meeting visual acuity requirements, are essential for reliable inspections and reports.

FAQs

1. What is the difference between dye penetrant testing and liquid penetrant testing?

A: Dye penetrant testing, also known as liquid penetrant testing, encompasses the same procedure. Both methods involve the application of penetrants to identify surface defects, with the main distinction lying in terminology preference.

2. What are the two types of penetrants used in liquid penetrant examination?

A: Liquid penetrant examination commonly utilizes visible dye penetrants and fluorescent penetrants. Visible dye penetrants contain coloured dyes visible to the naked eye, while fluorescent penetrants emit visible light under ultraviolet (UV) radiation for enhanced sensitivity.

3. What are the prerequisites for personnel conducting liquid penetrant testing?

A: Personnel conducting liquid penetrant testing must adhere to industry standards such as ASME Section V. They should be trained and qualified according to ASNT norms, with clear visual acuity and annual eye tests for near vision and colour blindness.

References

1. ResearchGate

2. NDE ED