Table of Content

Standards for Welding Positions

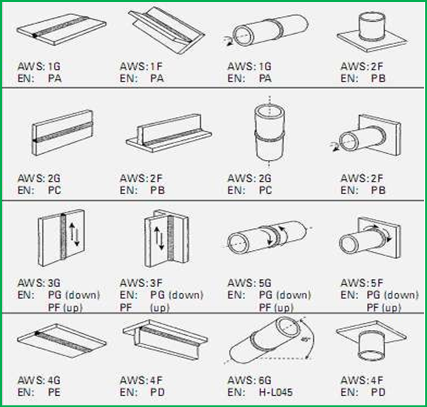

1. AWS D1.1, European Welding Standard EN 287 – 1, ASME IX:

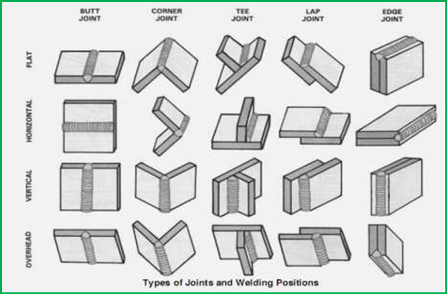

- It is very important for the weld inspector to know the position, or location of a joint relative to the horizon, because it may determine what welding process, methods, and techniques can be used.

- Welding Inspection is usually easiest when the welder can work on a joint located on a flat, horizontal surface, such as on a table or bench. However, Welded Joints in the field may be located in a variety of positions relative to the welder and to the horizon, as shown below.

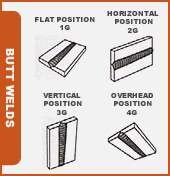

What are the 4 Welding Positions?

You can perform fillet and groove welds in these basic positions:

- Flat Butt Weld Position

- Horizontal Butt Weld Position

- Vertical Butt Weld Position

- Overhead Butt Weld Position

Welds with a flat position, horizontal position, vertical position, and overhead position. F stands for fillet weld, while G is a groove weld. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. A groove weld is made in a groove between workpieces or between workpiece edges.

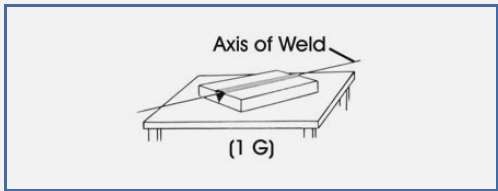

Flat Butt Weld Position – 1G

In this position, the axis line of the weld must not incline more than 15° from the horizon and the face of the weld must be on top. Welders often refer to flat-position welding by the nonstandard term downhand welding.

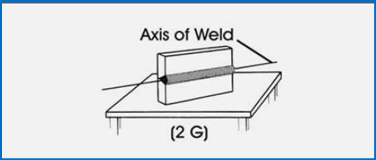

Horizontal Butt Weld Position – 2G

In this position, both plates are perpendicular to the bench top, but the axis of the weld remains horizontal. The lower surface of the groove helps somewhat to hold the molten weld metal in place.

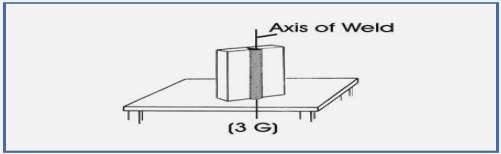

Vertical Butt Weld Position – 3G

In this position, the axis of the weld is perpendicular to the bench top and more difficult than in the flat and horizontal positions. The two plates and the axis of the weld are inclined more than 15° in reference to the horizontal bench top.

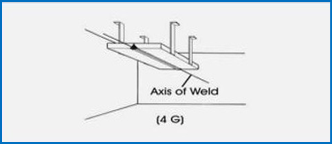

Overhead Butt Weld Position – 4G

In this position, the axis of the weld and the plates are horizontal, but the face for welding is downward. Welding in the overhead position is very difficult because there’s nothing to help overcome the force of gravity. A welder must have a high degree of skill to make sound welds consistently in this position.

All types of welding Brazing and Soldering process, (WPS / PQR ) and welder qualification, soldering technician qualification & brazing operator qualification. We have a strong client base for WPS approval in India. Welder qualification in Chennai, Welder qualification and WPS approval in Trichy, Welder Certificate in Pondichery, Salem, Kadaloor, Bangalore, etc.

References:

1. Red-D-Arc