Table of Content

- Introduction

- What are Industrial Valves?

- List of industrial valves manufactured by DomBor

- Different Applications of Industrial Valves

- Materials Used in Making Valves

- Components of Valve

- Conditions for Operation of Different Valves

- Conclusion

- Key Takeaways

- FAQs

Introduction

In the intricate operational framework of the oil and gas industry, few components embody complexities as profoundly as valves.

These unassuming yet integral devices act as guardians, regulating the flow and pressure within the expansive network of pipelines and machinery that intertwines this sector.

When considering the pivotal components essential to this industry's functionality, valves emerge as keystones.

Their fundamental role lies in meticulous regulation, managing the intricate dynamics of fluid and gas flow, and exerting control over pressure, temperature, and flow rates throughout the extensive web of Pipelines that define this sector.

Valves, essentially, function as gatekeepers, wielding the power to permit or restrict the movement of critical resources at various stages, including extraction, transportation, and refining processes.

Their undeniable relevance orchestrates the seamless functionality of this vast industrial domain.

However, contemplate the absence of these seemingly inconspicuous components; the repercussions would resonate profoundly.

Without valves, the industry's operational pathways would stumble, leading to a chaotic disruption of resource flow.

From the precision of drilling operations to transportation logistics, the absence of these unassuming yet indispensable devices would trigger an operational standstill, fracturing supply chains and inflicting a profound and far-reaching impact on the global economy.

What are Industrial Valves?

"A valve is a mechanical device designed to regulate, control, or direct the flow of fluids (liquids, gases, or slurries) within a piping system by opening, closing, or obstructing pathways."

Often underestimated in their significance, valves epitomize the silent components critical to the relentless machinery of the Oil and Gas Industry.

Over time, a multitude of suppliers and companies have pursued relentless innovation, crafting unique valve designs tailored precisely to the nuanced operational requirements of this sector.

These innovations span a spectrum, encompassing various valve types and similar components, harnessing advancements to enhance efficiency, endurance, and safety within this dynamic domain.

Among these innovations, the contributions of brands like Dombor resonate, showcasing a commitment to engineering excellence.

Their pioneering efforts stand as a testament to the evolving landscape of valve technology, shaping and strengthening the industry's operational capabilities through the development of tailored valve solutions.

This continuous drive towards innovation underscores the industry's resilience, continually enhancing its ability to navigate challenges and elevate operational standards within the ever-evolving realm of oil and gas production.

List of industrial valves manufactured by DomBor

DomBor Valve is a reputable manufacturer meeting the demand for comprehensive valve solutions with a foundation built on extensive industry experience, a trusted supply network, cutting-edge production machinery, digital design capabilities, and a commitment to quality. The industrial valves manufactured by DomBor (categorised by design) include:

1. Butterfly Valves

Engineered with a lightweight and compact design, DomBor's butterfly valves are adept at integration with large-diameter pipes handling liquid and gas mediums in Non-destructive Evaluation oil and gas operations.

This range includes high-performance, triple-offset, and flange butterfly valves, tailored for stringent operational requirements within the NDT in the oil and gas industry.

The types of butterfly valves they manufacture include:

- High-Performance Butterfly Valves

- Triple Offset Butterfly Valves

- Concentric Butterfly Valves

- Wafer Butterfly Valves

- Lug Butterfly Valves

- Flange Butterfly Valves

- Metal Seated Butterfly Valves

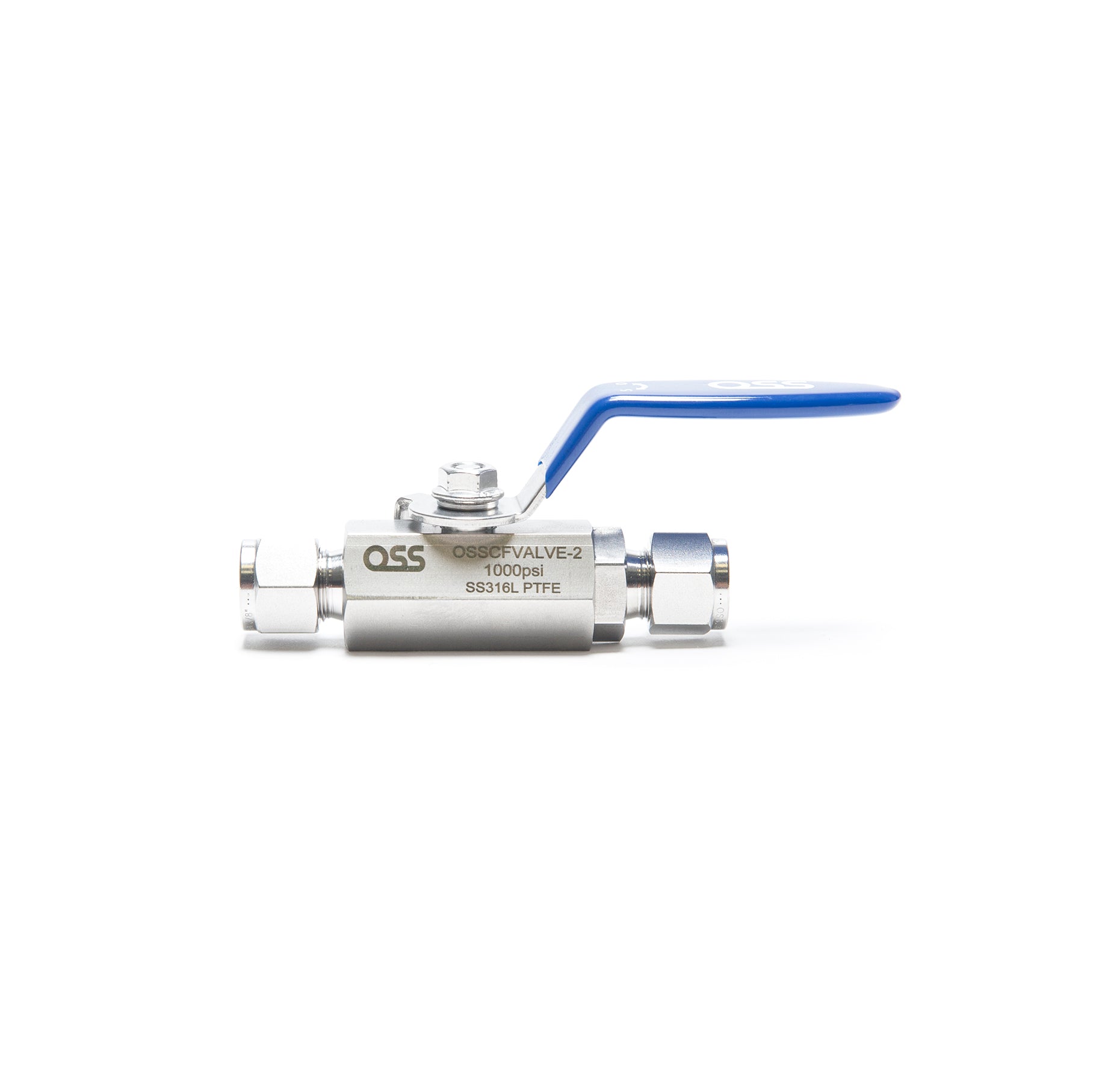

2. Ball Valves

DomBor's industrial ball valves, including floating, way, and port ball valves, boast a compact build ideal for diverse piping systems in NDT Applications.

These valves offer versatile and reliable solutions for fluid control, crucial for Non-destructive Testing Supervisor roles overseeing Visual Inspection solutions for oily products.

The types of ball valves they manufacture include:

- 3 Way Ball Valves

- Double Block and Bleed Ball Valves

- Floating Ball Valves

- Fully Welded Ball Valves

- Rising Stem Ball Valves

- Side Entry Ball Valves

- Split Body Ball Valves

- Top Entry Ball Valves

- Trunnion Ball Valves

- V Port Ball Valves

3. Gate Valves

The range of gate valves from DomBor, such as wedge, slab, and knife gate valves, plays a pivotal role in ensuring unobstructed fluid flow or complete restriction, essential for Inspection methods in the oil and gas industry.

The types of gate valves they manufacture include:

- Knife Gate Valves

- Resilient Seated Gate Valves

- Slab Gate Valves

- Stainless Steel Gate Valves

- Wedge Gate Valves

4. Check Valves

DomBor's swing check valves and lift check valves provide high-pressure handling capabilities, essential for Oil and Gas Inspection safety protocols, preventing backflow in critical pipelines.

The types of check valves they manufacture include:

- Dual Plate Check Valves

- Lift Check Valves

- Non-Slam Check Valves

- Swing Check Valves

- Tilting Disc Check Valves

5. Globe Valves

DomBor's range of globe valves, including straight pattern and angle globe valves, ensures versatile usage and optimal full-closing qualities, vital for maintaining inspection safety standards within the oil and gas industry.

The types of globe valves they manufacture include:

- Angle Globe Valves

- Bellows Sealed Globe Valves

- Straight Pattern Globe Valves

- Y Pattern Globe Valves

6. Plug Valves

From eccentric plug valves to sleeved plug valves, DomBor's selection ensures immediate on/off operation and tight sealing, ideal for inspection safety in various oil and gas applications.

The types of plug valves they manufacture include:

- Double Block and Bleed Plug Valves

- Eccentric Plug Valves

- Lubricated Plug Valves

- Sleeved Plug Valves

7. Actuated Valves

DomBor's pneumatic, electric, and hydraulic actuated valves offer adaptable control, suitable for inspection methods and ensuring safety measures in Oil and Gas Inspections.

The types of actuated valves they manufacture include:

- Electric Actuated Valves

- Hydraulic Actuated Valves

- Pneumatic Actuated Valves

8. More Valves

Encompassing needle valves, cryogenic valves, lined valves, and other variants, these valves are designed to withstand intense pressure, facilitating safe inspection practices in the oil and gas industry while ensuring seamless flow maintenance. These include:

- Cryogenic Valves

- Forged Valves

- Lined Valves

- Needle Valves

- Pressure Seal Valves

- Special Material Valves

- Steam Traps

- Y Strainers

The importance of quality valves lies in their fundamental role within engineering systems.

They ensure precise regulation of fluid and gas flow, pressure management, and the ability to control and direct the movement of crucial resources within complex systems.

DomBor's array of valves addresses specific engineering needs, offering diverse functionalities tailored to different operational requirements across industries.

These valves are meticulously designed with unique features to optimize performance, durability, and safety within intricate engineering applications.

Different Applications of Industrial Valves

The different applications of valves across industries include:

Power Generation

Valves play a critical role in thermal power plants, Nuclear Power Plants, and fossil fuel power plants.

They assist in regulating steam, controlling cooling systems, and ensuring safety measures in core spray systems and pump isolation.

Oil and Gas Industry

Industrial valves are indispensable in oil and gas operations, including pipeline networks, gasification plants, and LNG transportation systems.

They regulate the flow of oil, gas, and other fluids while ensuring safety measures in flare inlets and recovery systems.

Petrochemical and Chemical Plants

Valves are used in petrochemical plants to handle a range of substances like brine, CO2 vapor, propylene, ethylene, and other corrosive chemicals.

They aid in controlling processes and ensuring safety in critical applications.

Cryogenic Applications

Valves designed for cryogenic conditions are essential in industries dealing with liquid gases, LNG transportation, and cryogenic gasification.

These valves maintain efficient operations in extremely low-temperature environments.

Paper and Pulp Industry

Valves facilitate fluid control in the paper and pulp industry, handling liquids, steam isolation, boiler water, slurries, and lime within paper roll machines.

Heating Systems

In central heating, heat exchange stations, and steam pipe networks, valves regulate hot water flow, steam distribution, and system isolation for efficient heating operations.

Water Treatment and Desalination

Valves are crucial in seawater desalination systems, saltwater applications, and core spray systems within Nuclear Plants, ensuring efficient fluid control and system safety.

Industrial valves serve as essential components across multiple sectors, ensuring the smooth operation, safety, and efficiency of various processes within complex industrial systems.

The applications of valves within the Oil and Gas Industry include the following:

Fast Shut Offs and Tight Sealing

Within oil and gas technology, valves provide rapid shut-offs and secure sealing mechanisms, crucial for maintaining safety and integrity during emergencies or maintenance.

Flow Control

An integral aspect of oil and gas management, valves regulate fluid flow, enabling precise control over quantities and directions, and optimise operational efficiency.

High-Pressure Flow Control

Specialised valves manage high-pressure flows, a critical feature in oil and gas services, ensuring safe and controlled movement of fluids under extreme pressure conditions.

Pressure Management

Vital for oil and gas management, valves help maintain and adjust optimal pressure levels within the system, guaranteeing safe and efficient operations.

Channeling of Petroleum Products

In oil and gas services, specific valves facilitate the precise routing and transfer of petroleum products, ensuring accurate handling across diverse operational points.

Management of Semi-Solid Inputs

Within oil and gas technology, valves control semi-solid inputs like slurries, essential for efficient processing and transport in the oil and gas infrastructure.

Pipeline Networks

Valves serve as critical regulators, facilitating the safe and efficient movement of oil, gas, and various fluids through extensive pipeline networks, ensuring continuous and controlled transportation.

LNG Transportation Systems

Industrial valves are pivotal in managing the transportation of liquefied natural gas (LNG), ensuring secure and controlled transfer, vital for safe and efficient long-distance transport.

Gasification Plants

Valves play a crucial role in controlling processes within gasification systems, contributing significantly to efficient gas production, storage, and distribution, ensuring operational reliability.

Field Recovery Systems

Essential for managing field recovery operations, valves enable controlled flow and extraction of oil and gas resources from the extraction sites, ensuring operational efficiency and resource maximisation.

In the oil and gas industry, the strategic deployment of industrial valves ensures not just the regulation but the precise control of resource flow throughout the extraction, transportation, and processing phases, guaranteeing operational efficiency and safety within these multifaceted systems.

Materials Used in Making Valves

The material used in the manufacturing of valves include:

Stainless Steel

Valves crafted from stainless steel, known for exceptional corrosion resistance, durability, and suitability for harsh environments, ensure prolonged service life and reliability. Non-destructive evaluation (NDE) verifies its integrity.

Cast Steel

Employed for its robustness and adaptability, cast steel forms sturdy valve bodies, validated through non-destructive testing (NDT) methods to ensure structural integrity.

Forged Steel

Valves constructed from forged steel exhibit superior strength and reliability, critical for high-pressure applications. NDT techniques certify their resilience and durability.

Components of Valve

The components of Valves include:

Body

The primary casing housing valve internals, are thoroughly inspected using NDT methods to detect potential flaws or defects, ensuring structural soundness.

Bonnet

Protective covering allowing access for maintenance, NDT ensures its integrity for continued safety and operational efficiency.

Ports

Openings facilitating fluid flow, undergo thorough Non-destructive Evaluation (NDE) to confirm optimal functionality and prevent potential leaks.

Actuator

Mechanism initiating valve movement, evaluated through NDT Techniques for consistent performance and reliability.

Disc, Seat, Stem

Vital components verified via NDT Methods to ensure proper sealing, fluid control, and structural integrity.

Spring, Trim

NDT Inspections validate these internal parts, certifying their condition and functionality within the valve assembly.

Conditions for Operation of Different Valves

Temperature and Pressure

Valves are engineered to operate within specific temperature and pressure ranges. NDT verifies their capability to withstand varying conditions, ensuring safe and efficient functionality.

Pressure Relief

NDT methods certify relief valves for reliable performance during pressure spikes, averting potential hazards.

Corrosive Conditions

Valve materials and structures are NDT inspected for resistance against corrosive environments, ensuring longevity and safety.

Non-destructive Testing (NDT) Techniques, including Ultrasonic Testing (UT), Radiographic Testing (RT), Magnetic Particle Testing (MPT), Liquid Penetrant Testing (LPT), and tubular inspections, are pivotal in evaluating valve materials, components, and operational conditions, safeguarding against defects, ensuring reliability, and enhancing safety within the oil and gas industry.

Ultrasonic Testing (UT)

Detects internal defects using sound waves.

Radiographic Testing (RT)

Utilizes X-rays to identify flaws within valve components.

Magnetic Particle Testing (MPT)

Reveals surface cracks or defects using magnetic fields.

Liquid Penetrant Testing (LPT)

Identifies surface flaws by applying penetrant and developer.

NDT techniques ensure the reliability and safety of valves by identifying potential defects or flaws, crucial for the oil industry to maintain operational efficiency and prevent potential hazards.

Conclusion

Valves serve within the intricate framework of the oil and gas industry, regulating the flow, pressure, and movement of crucial resources across complex systems.

Without these unassuming yet critical components, the repercussions could be catastrophic. The absence of valves could result in chaos within the operational landscape, leading to a complete breakdown in the flow and regulation of crucial resources.

This disruption would echo through the industry, causing operational standstills, halting production, and severely disrupting supply chains. Such a scenario wouldn't just impact the industry's functionality; it could also have far-reaching effects on the global economy.

Valves play an instrumental role in sustaining the continuity of operations, ensuring that the oil and gas industry functions seamlessly.

Their ability to regulate flow, manage pressure, and control the movement of resources across this vast industrial domain underscores their pivotal role in maintaining operational stability and global economic equilibrium.

Key Takeaways

- Valves, often underestimated, are critical components ensuring the smooth operation of oil and gas systems by controlling fluid flow, pressure, and resource movement.

- Manufacturers like DomBor exemplify engineering excellence, providing tailored valve solutions vital for maintaining safety, efficiency, and reliability across diverse industrial applications.

- Non-destructive testing (NDT) methods like UT, RT, MPT, and LPT ensure the structural integrity of valves, detecting flaws crucial for maintaining safety and reliability within the oil and gas industry.

FAQs

1. What is a valve used in oil and gas?

A: Valves in the oil and gas industry regulate the flow of fluids like oil, gas, and various substances within the extensive network of pipelines and equipment.

They manage pressure, control flow rates, and ensure the safe movement of resources crucial for operational efficiency in oil and gas production.

2. What valves are on an oil rig?

A: Oil rigs typically use various types of valves, including ball valves, gate valves, check valves, and control valves.

These valves are crucial for managing fluid flow, controlling pressure, and facilitating safe and efficient operations on the rig.

3. How many valves are in a refinery?

A: The number of valves in a refinery can vary significantly based on its size and complexity.

Refineries often have thousands of valves, ranging from control valves to isolation valves, distributed across different units like distillation columns, reactors, and storage tanks.

4. Why are valves used?

A: Valves are used in the oil and gas industry to control and regulate the flow of fluids, maintain pressure levels, and manage the movement of resources within pipelines and equipment.

They are essential for ensuring safety, operational efficiency, and the smooth functioning of oil and gas systems.

5.What is valve size?

A: Valve size refers to the diameter of the valve's opening or the nominal pipe size it fits into.

Valves come in various sizes, ranging from small sizes like fractions of an inch to large sizes exceeding several feet in diameter, catering to different operational needs within oil and gas facilities.