Table of Content

- What is Visual Inspection?

- Inspector Visual Requirements

- Procedure of Visual Inspection of Welds

- Weld Preparation Techniques

- Visual Inspection in the Future

- Key Takeaways

Visual inspection after welding is very useful in evaluating quality, even if other testing methods are to be employed. As welding progresses, surface flaws such as cracks, porosity, and unfilled craters can be detected only by Visual Inspections, leading to repairs or rejection of the work. Welds must be cleaned from slag to inspect for surface flaws possible. A 10x magnifying glass helps detect fine cracks and other faults. As indicated before, a borescope and dental mirrors, are useful for inspection inside vessels, pipes, or confined areas.

What is Visual Inspection?

Visual Inspection is the most popular and widely used of the non-destructive inspection techniques. Completed welds should be checked according to the plans and the specifications. The most common welds that need to be inspected in the field are fillet welds. Fillet Welds are designed based on their leg sizes. If the leg is under the specified dimension, the required strength is less than what the joint was designed for. The throat of the weld should be checked also.

Also, Read The Significance of Visual Inspection in NDT

Inspector Visual Requirements

Performed with or without corrective lenses, to prove near vision acuity on Jaeger J2 at not less than 12 inches and a colour perception test. The objective of visual inspection at this stage is not only to detect nonpermissible faults but all procedure details. If the plans show a fillet weld at 5/16 inches, then each leg of the weld needs to measure to that dimension.

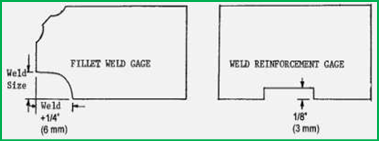

A fillet weld gauge is the standard tool to check weld sizes. The fillet weld gauge has two corners for checking leg sizes and two corners for checking the throats of the weld. An explanation of how to use the fillet weld gauge is shown below:

The initial procedures taken by the Welding Inspector are:

a. Details to Check Before the Welding:

- The materials to be welded and the related standards (ASME, ASTM,);

- Welder Qualification Certificate, drawings, and related documents;

- Welder equipment and electrodes, including storage and drying systems;

- Welding edge preparations and correct bevels;

- Root openings;

- Clearance of backing strip or ring;

- Overall alignment and fit up;

- Welding Procedures during the welding

b. Details to Check During the Welding:

- Preheat and inter-passing temperature;

- Cleaning, chipping, grinding or gouging;

- Structural defects and discontinuities;

- Post-heating temperature, when specified.

c. Details to Check After the Welding:

- Dimensional accuracy of the weldment, using fillet weld gages or rulers, as shown above;

- Conformity to drawing and procedure requirements;

- Acceptability of welds with regard to appearance and fabrication quality;

- The presence of any unfilled craters, undercuts, cracks, overlaps;

- Post-heating temperature, when specified.

d. Weld Joint Preparation:

The first step in making a sound weld is to make sure the joint is correctly cleaned using a stiff wire brush or a grinder for cleaning the base metals. The portion of the base metal to which the ground clamp will be attached must also be cleaned. Poor contact with the ground clamp will create resistance in the welding circuit and could result in poor weld quality.

Preheat before Welding should be taken according to procedures. All unpainted surfaces have to be free from loose or thick scale, slag, rust, moisture, grease, or other foreign material.

Step-by-step Procedure of the Visual Inspection of Welds

Visual inspection is a crucial method for evaluating the weld quality of a test subject. The visual inspection method is widely used due to its simplicity, cost-effectiveness, and ability to detect surface flaws. Advantages of visual inspection include its suitability for onsite assessments, immediate results, and minimal equipment requirements. Types of visual inspection techniques vary based on the application and can include direct visual examination, remote visual inspection, and video inspection.

1. Before Inspection -

Preparation:

Gather necessary tools such as magnifying glasses, flashlights, and inspection gauges. Ensure adequate lighting and access to the weld area. Review welding specifications and standards applicable to the project.

2. During Inspection -

Inspection Techniques:

- Direct Visual Examination: Observe welds directly using the naked eye or with the aid of magnification tools.

- Remote Visual Inspection: Use cameras or borescopes to examine welds in confined or inaccessible areas.

- Video Inspection: Record videos of welds for detailed analysis and documentation.

3. After Inspection

Defect Identification:

- Surface Flaws: Look for indications of cracks, porosity, incomplete penetration, undercutting, or other discontinuities.

- Weld Geometry: Check for proper weld size, shape, and alignment according to specifications.

- Joint Integrity: Verify the integrity of the weld joint and assess its suitability for the intended application.

Documentation:

- Record Inspection Findings: Document observations, measurements, and any detected defects.

- Compliance Reporting: Prepare reports detailing compliance with welding procedures and standards.

- Nonconformance Reporting: Identify and document any deviations from acceptance criteria and recommend corrective actions.

Following these step-by-step procedures before, during, and after inspection, can aid inspectors in effectively assessing welds, identifying defects, and maintaining quality standards in welding processes.

Read More, Welding Procedure Specification

Weld Preparation Techniques

Proper weld preparation helps create clean, well-aligned surfaces, which are crucial for achieving strong and durable welds. Visual inspection plays a significant role in verifying the effectiveness of weld preparation techniques. Some preparation techniques to be carried out on welds before inspection include:

1. Cleaning:

Thoroughly clean the weld area to remove any debris, dirt, oil, or contaminants that could obscure defects during inspection. Use wire brushes, solvents, or grinding tools as necessary.

2. Surface Smoothing:

Ensure that the welding surface is smooth and free of rough edges, burrs, or irregularities that could interfere with the inspection process or mask defects.

3. Surface Marking:

Mark the weld area with appropriate identification, such as reference points or inspection locations, to facilitate accurate inspection and documentation.

4. Access Preparation:

Ensure proper access to the weld area for inspection. This may involve removing obstacles, adjusting lighting, or using inspection tools such as borescopes for internal inspections.

5. Pre-Inspection Verification:

Conduct a preliminary visual inspection to assess the cleanliness, alignment, and overall condition of the weld area before proceeding with formal inspection procedures.

These preparation techniques help ensure that the weld area is optimally prepared for inspection, allowing inspectors to accurately assess weld quality and detect any defects or discrepancies.

Visual Inspection in the Future

Visual inspection methods have evolved significantly, driven by technology, automation, and AI. Modern techniques integrate imaging technology, robotics, and AI algorithms for improved efficiency and accuracy.

Visual Inspection Methods of the Future include the following:

1. Automated Visual Inspection: Integrates robotics, computer vision, and AI for precise defect detection and analysis.

2. AI-Assisted Visual Inspection: Utilizes AI algorithms to analyze images and videos, enhancing defect identification and decision-making. AI algorithms provide predictive maintenance insights, enabling proactive defect prevention and optimization of inspection processes.

3. Remote Visual Inspection (RVI): Employs cameras, borescopes, or Robotic Systems for Inspections in inaccessible or hazardous areas. Drones equipped with advanced cameras and sensors, assist in infrastructure inspections and agriculture monitoring.

Automation and AI improve inspection efficiency, reduce costs, and enhance accuracy, leading to improved productivity and quality control in various industries.

Key Takeaways

- Visual inspection has evolved from manual assessments to sophisticated techniques integrating technology and AI, leading to improved efficiency and accuracy.

- The future of visual inspection involves automation, AI, and remote inspection techniques, enabling precise defect detection, predictive maintenance, and enhanced productivity across industries.

- Industries such as manufacturing, construction, and healthcare are leveraging advanced visual inspection methods to ensure product quality, structural integrity, and compliance with standards.

FAQs

1. How has visual inspection evolved with time?

A: Visual inspection methods have advanced significantly with technology, automation, and AI. From manual assessments, modern techniques integrate imaging technology, robotics, and AI algorithms for precise defect detection and analysis.

2. What industries benefit from advanced visual inspection methods?

A: Various industries benefit from advanced visual inspection, including manufacturing, construction, oil and gas, and healthcare. These industries utilize automated visual inspection systems, AI algorithms, and remote inspection techniques to enhance productivity and quality control.

References:

1. Picryl

2. AQC Inspection

3. Ceyrek Muhendis