DeltaFlux

Since 1992 Delta Flux has been a leading company in designing and producing systems and machines in the NDT field specializing in MPI (Magnetics Particles Inspection) and PT (Dye and Fluorescent Penetrant Inspection) devices.

Overview

Since 1992, Delta Flux has specialized in the design and tailor-made construction of complete machinery and systems for carrying out superficial non-destructive testing, using magnetoscopy or penetrating liquids.

Delta Flux offers its customers everything they need to carry out non-destructive surface testing:

All our machines are designed and built to measure for our customers and adapt perfectly to each company's specific needs, timing, available space, workflows, and volumes. In addition to the initial supply of the machinery, we also take care of the supply of all the accessories, spare parts and consumables necessary for the daily operation of a surface inspection machine.

Products

Services

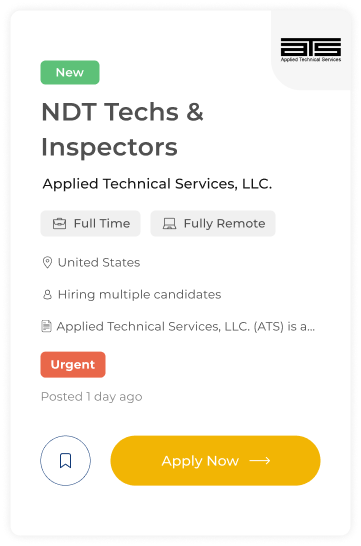

Ads