EISHIN KAGAKU CO.LTD.

Establishment of the company (Chiyoda-ku, Tokyo) Manufacture and sales of non-destructive inspection products [Dyeing penetrant flaw detector Red Mark / Fluorescent penetrant flaw detector Neo Glow / Magnetic particle flaw detector Magnatron]

Overview

Establishment of the company (Chiyoda-ku, Tokyo) Manufacture and sales of non-destructive inspection products [Dyeing penetrant flaw detector Red Mark / Fluorescent penetrant flaw detector Neo Glow / Magnetic particle flaw detector Magnatron] Manufacture and sales of ultraviolet flaw detector black light

1958 [Showa 33] March Established a manufacturing plant for penetrant and magnetic particle testing agents in Kawasaki City.

1960 [Showa 35] August By August 1968, sales offices were opened in Kawasaki, Nagoya, Osaka, and Hiroshima.

1961 [Showa 36] Manufacture and sales of fluorescent penetrant flaw detector Neo-Glow Unit, which is certified by the U.S. Far East Air Force and the Defense Agency. Manufacture and sales of portable magnetic particle flaw detector Handy Magna.

1963 [Showa 38] July Established Chiba Factory in Kashiwa City, Chiba Prefecture

1967 [Showa 42] Development and sales of dyeing penetrant flaw detector Red Mark <Special> for nuclear power equipment Manufacture and sales of magnetic particle flaw detector Magnastar Research, development, and sales of plating crack test pieces for penetrant testing September 1969 Relocated head office to Higashi-Shimbashi, Minato-ku, Tokyo

1970 [Showa 45] August Fluorescent penetrant flaw detection agent was certified by McDonnell Douglas and Boeing in the United States.

1973 [Showa 48] Fluorescent penetrant flaw detection agent certified by the U.S. Air Force

1975 [Showa 50] Developed and sold a series of leak test agents including foam leak test agent GL-1B.

1978 [Showa 53] R&D and sales of Redmark (NT) DL family of incombustible dye penetrant flaw detection agents

May 1980 [Showa 55] Fluorescent penetrant flaw detection agent for aircraft was approved by General Electric Company of the United States and Rolls-Royce of the United Kingdom.

1982 [Showa 57] Licensed technology for fluorescent magnetic particles to Aldrox in the U.S. Developed and sold an ultrasonic imaging system

1984 [Showa 59] June Licensed technology for fluorescent magnetic powders to British Blend Chemical Company

1986 [Showa 61] Penetrant inspection agent revised based on the transition of MIL-I-25135 to SAE-AMS2644 becomes the first U.S. Air Force certified product in Japan.

June 1989 Became the sole agent in Japan for ultrasonic flaw detectors manufactured by Stavely Inc. in the United States.

June 1994 Established R&D Center in Kashiwa City, Chiba Prefecture

April 2004 Established East Japan Sales Office in Kashiwa City, Chiba Prefecture

2007 [Heisei 19] Acquired ISO 9001 certification at the factory

Moved the Chiba Factory to Joso City, Ibaraki Prefecture and established the Ibaraki Factory

2008 [Heisei 20] Acquired general construction business (machinery and equipment installation work) license

January 2014 [Heisei 26] Relocated Hiroshima Sales Office

November 2017 Construction of L building (training and experiment building) on the premises of the Ibaraki factory

November 2018 [Heisei 30] Acquired ISO14001 certification at Ibaraki Plant

February 2019 [Heisei 31] Installed PT and MT devices in the L building (training and experiment building) in the Ibaraki factory. Started accepting requests for tests, tours and demonstrations.

Products

Services

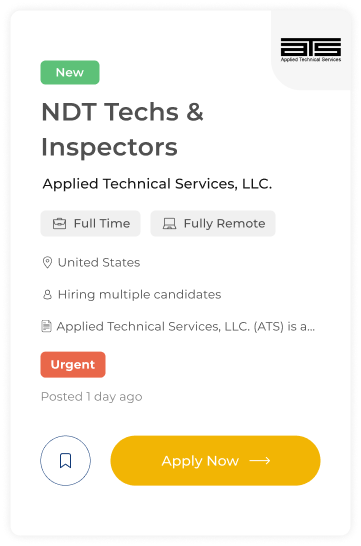

Ads