NDT PLUS s.r.l.

NDTPLUS srl was born as a provider of non-destructive testing services for the oil & gas, chemical, industrial and civil sectors, developing specific sector skills such as the control of pressure equipment, valves, piping and flare tips.

Overview

NDT plus srl is a young and dynamic company created to meet the needs of a constantly evolving industrial sector.

Supported by proven experience in the non-destructive testing sector alongside leading companies, we have decided to enter the field directly with the provision of non-destructive testing, training and business consultancy services in the NDT sector.

What is proposed is guaranteed by continuous training of technical staff and the use of cutting-edge instrumentation.

Aware of having to maintain the successes achieved so far and of having to respect the expectations of an increasingly demanding clientele, NDT Plus proposes itself with a philosophy oriented towards the consolidation and continuous improvement of the NDT service.

Products

Services

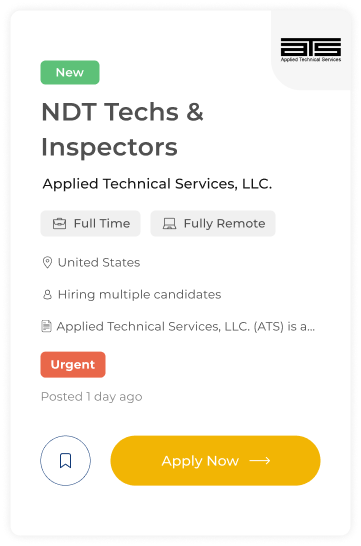

Ads